Browse Products by Collection

we have exported drill bits to more than 60 countries. All the Tricone bit and PDC bit are manufactured strictly according to ISO.

Hot Sale Products

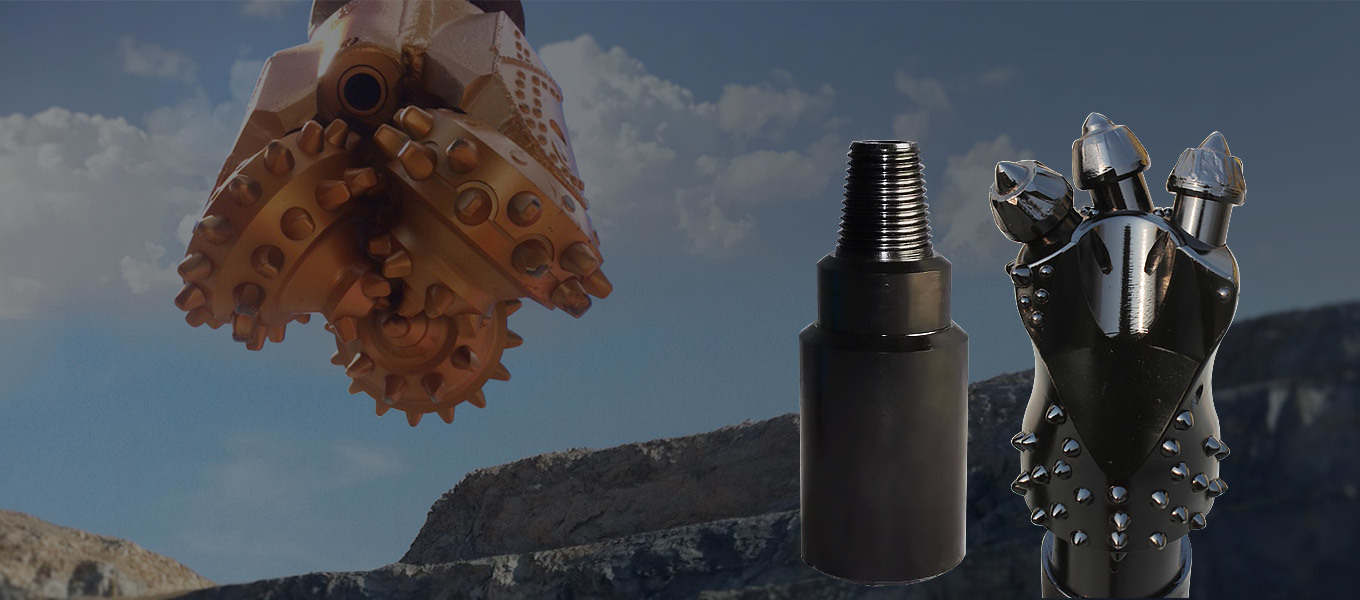

High-efficiency Drill Bit Solutions for Reliable Performance in a Wide Range of Drilling Environment.

CROSSING BIT

Excellent Manufacturer For

Quality PDC Bits and Tricone Bits

Hebei Crossing Drill Bit Manufacture Co., Ltd is one of the leading manufacturer for Quality PDC bits and Tricone bits in North of China ,we have exported drill bits to more than 60 countries.All the Tricone bit and PDC bit are manufactured strictly according to ISO

Experience

Exporting Country

Specification

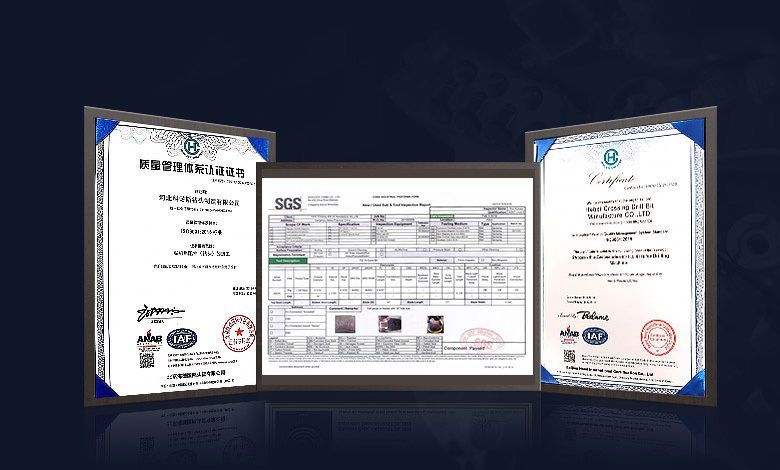

Quality Control

Advanced Technology And Equipment, International Standard. R&D Center For Drilling Tools. High Precision CNC Machines.

We have exported drill bits to more than 30 countries. All the Tricone bit and PDC bit are manufactured strictly according to API7-1 standard and ISO.

Client Case

Abu Dhabi: 9 7/8" IADC737 tricone bit

Argentina: 12 1/4”tricone bit IADC code 637

Indonesia: 8 1/2”IADC code 537 tricone bit

Mexico: 17 1/2" IADC637 tricone bit

News & Press

Optimizing Workflow: Strategies for Using HDD Hole Openers Effectively

The Essential Guide to HDD Hole Openers: Maximizing Efficiency in Industrial Drilling

Stay Ahead of the Curve with Tricone Milling Cutters: Revolutionizing Industrial Applications