Optimizing Workflow: Strategies for Using HDD Hole Openers Effectively

Apr 11,2025

Optimizing Workflow: Strategies for Using HDD Hole Openers Effectively

Table of Contents

- 1. Introduction to HDD Hole Openers

- 2. Understanding Horizontal Directional Drilling (HDD)

- 3. The Importance of HDD Hole Openers in Projects

- 4. Types of HDD Hole Openers: A Comprehensive Overview

- 5. Choosing the Right HDD Hole Opener for Your Project

- 6. Best Practices for Using HDD Hole Openers Effectively

- 7. Troubleshooting Common Issues with HDD Hole Openers

- 8. Case Studies: Successful Implementation of HDD Hole Openers

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to HDD Hole Openers

Horizontal Directional Drilling (HDD) has transformed the way that various industries approach underground installations. Essential to this technology are HDD hole openers, which play a crucial role in preparing boreholes for the installation of pipes, cables, and other utilities. Understanding how to effectively use these tools can significantly enhance workflow, reduce operational costs, and improve overall project outcomes.

2. Understanding Horizontal Directional Drilling (HDD)

HDD is a trenchless method used to install underground utilities in a way that minimizes surface disruption. This technique involves drilling a pilot hole along a predetermined path and then enlarging it using hole openers. This process is advantageous for several reasons:

- **Reduced Surface Impact**: HDD minimizes environmental disturbance and is ideal for urban areas.

- **Cost Efficiency**: By reducing the need for extensive excavation, HDD can lower labor and restoration costs.

- **Versatility**: This method can be used for various materials, including soil, rock, and even water.

3. The Importance of HDD Hole Openers in Projects

Hole openers are critical in HDD operations as they allow contractors to enlarge the initial pilot hole to accommodate the installation of larger utilities. The efficient use of these tools can lead to:

- **Faster Installation Times**: Properly sized hole openers can significantly speed up the installation process.

- **Improved Borehole Quality**: Quality hole openers help in maintaining the integrity and alignment of the borehole.

- **Enhanced Safety**: Using the right tools reduces the risk of tool failure and associated accidents.

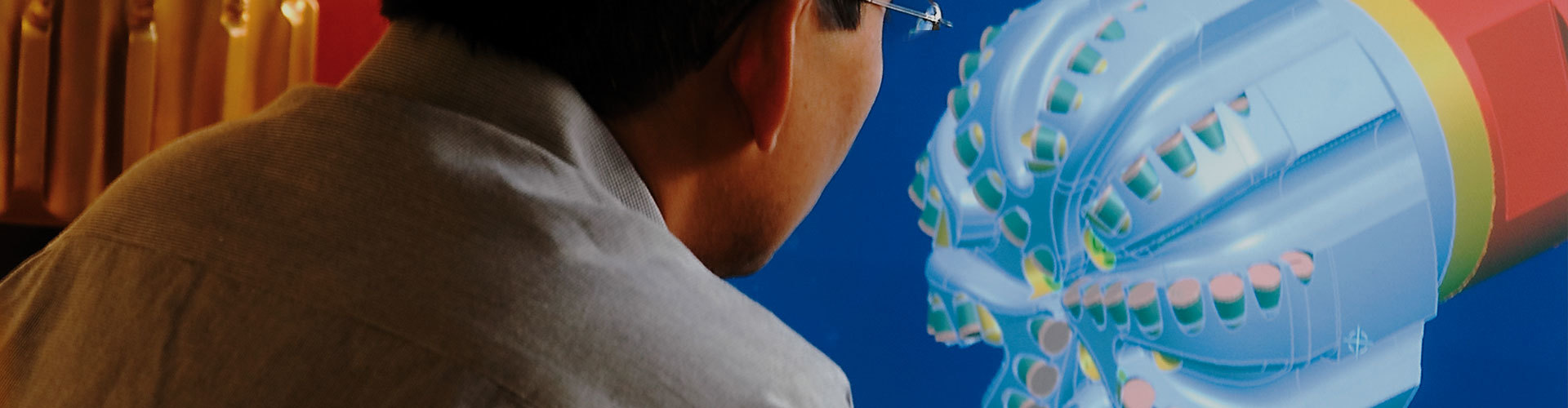

4. Types of HDD Hole Openers: A Comprehensive Overview

When selecting an HDD hole opener, understanding the various types available is essential for effective workflow optimization. Here are some common types:

- **Rolling Blade Hole Openers**: These are designed for use in soft to medium soils and can provide larger boreholes compared to traditional methods.

- **Tapered Hole Openers**: Ideal for rocky conditions, these openers feature a tapered design that reduces drag and provides better control during drilling.

- **Disc Hole Openers**: Equipped with multiple discs, these hole openers are effective for larger diameter installations and can handle a variety of ground conditions.

- **PDC (Polycrystalline Diamond Compact) Hole Openers**: Known for their durability, PDC openers are optimal for harder geological formations and can enhance drilling speed.

5. Choosing the Right HDD Hole Opener for Your Project

Selecting the correct HDD hole opener is crucial for optimizing workflow. Consider the following factors when making your selection:

- **Soil Type**: Different hole openers are designed for specific soil conditions. Assessing the geological formation is key.

- **Borehole Size and Depth**: Ensure the opener matches the required borehole diameter and depth for your project.

- **Operational Considerations**: Evaluate the drilling rig's compatibility with various hole openers to maximize efficiency.

6. Best Practices for Using HDD Hole Openers Effectively

To ensure optimal performance when using HDD hole openers, follow these best practices:

- **Conduct Thorough Site Surveys**: Before starting, conduct comprehensive surveys to understand soil conditions and potential obstacles.

- **Utilize Proper Techniques**: Implement drilling techniques that reduce stress on the hole opener and the rig.

- **Maintain Regular Equipment Checks**: Scheduled inspections of the hole openers and drilling equipment can prevent unexpected failures.

- **Train Operators**: Ensure that the team is well-trained in operating HDD equipment to avoid costly mistakes and enhance performance.

7. Troubleshooting Common Issues with HDD Hole Openers

Even with the best practices in place, issues may arise during drilling operations. Here are some common problems and their solutions:

- **Poor Borehole Quality**: This could be due to the wrong type of hole opener. Reassess the soil conditions and switch to a suitable opener.

- **Frequent Tool Failures**: Inspect for signs of wear and tear. Use high-quality materials for cuttings and ensure proper maintenance.

- **Slow Drilling Speed**: This can indicate improper use of the hole opener or the need for a more suitable tool. Adjust the drilling parameters accordingly.

8. Case Studies: Successful Implementation of HDD Hole Openers

Examining real-world applications of HDD hole openers highlights their benefits. Here are a couple of case studies demonstrating effective usage:

- **Case Study 1: Urban Utility Installation**: A city utility project employed rolling blade hole openers to install water lines without disrupting traffic. The result was a 30% reduction in project time and costs.

- **Case Study 2: Oil and Gas Sector**: An oil company faced rocky terrain for pipeline installation. By using PDC hole openers, they achieved a successful borehole with minimal downtime, enhancing overall productivity.

9. Frequently Asked Questions

What is the primary function of HDD hole openers?

HDD hole openers are designed to enlarge pilot holes for the installation of larger pipes or cables, improving the efficiency of underground utility projects.

How do I choose the right hole opener for my project?

Consider factors such as soil type, required borehole size, and the drilling rig’s specifications to select the most appropriate hole opener.

What maintenance is required for HDD hole openers?

Routine inspections, cleaning, and replacing worn components are essential to ensure optimal performance and longevity of hole openers.

Can HDD hole openers be used in all types of soil?

While many hole openers are versatile, specific types are optimized for particular soil conditions. Ensure you choose the right opener based on your project’s geological conditions.

What are the advantages of using PDC hole openers?

PDC hole openers provide durability and efficiency, making them ideal for challenging geological formations and promoting faster drilling operations.

10. Conclusion

Utilizing HDD hole openers effectively is crucial for optimizing workflow in underground utility projects. By understanding the different types of hole openers, selecting the right tools, and following best practices, contractors can enhance productivity, reduce costs, and ensure successful project completion. As we continue to innovate in the field of directional drilling, the importance of these tools will only grow, making it essential to stay informed and adaptable.

PREVIOUS:

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.