The Essential Guide to HDD Hole Openers: Maximizing Efficiency in Industrial Drilling

Apr 08,2025

---

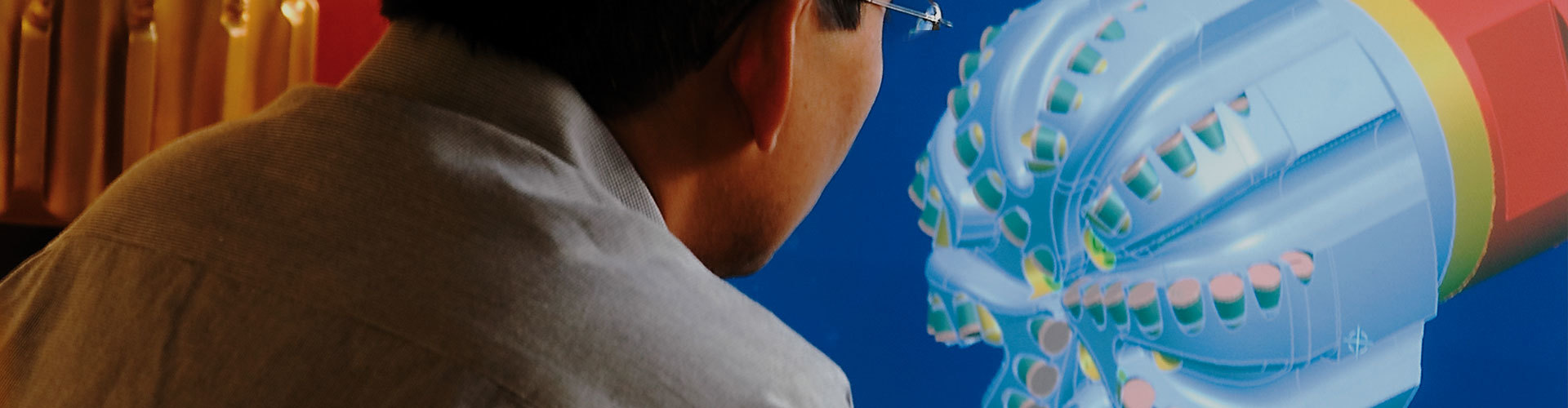

In the realm of industrial drilling, particularly in trenchless technology, the HDD (Horizontal Directional Drilling) hole opener plays a critical role. These specialized tools are designed to create larger diameter holes in a variety of subsurface conditions, facilitating the installation of pipelines, cables, and other infrastructure. Understanding the functionality and types of HDD hole openers can help professionals in the field make informed decisions that enhance operational efficiency.

HDD hole openers work by enlarging a pilot hole, which is first drilled using a smaller bit. The hole opener is then attached to a drill string and directed through the pilot hole, effectively expanding its diameter. This process allows for the installation of larger bore pipelines without the need for traditional trenching, which can be both time-consuming and disruptive to the surrounding environment.

There are several types of HDD hole openers available, each designed for specific applications. For instance, roller cone hole openers are ideal for drilling through hard rock formations, while fixed blade hole openers are better suited for softer soils. Understanding the geological conditions of the drilling site is crucial when selecting the appropriate HDD hole opener, as it can significantly impact the drilling performance and overall project success.

In addition to choosing the right type of hole opener, several best practices can help maximize efficiency when using HDD hole openers. First, ensuring that the equipment is well-maintained can reduce downtime and optimize drilling speed. Regular inspections and prompt replacements of worn components are essential for maintaining operational integrity.

Moreover, it's important to monitor drilling parameters, such as torque and pressure, during the drilling process. Adjusting these parameters according to the specific conditions encountered can prevent potential issues, such as excessive wear or equipment failure. Additionally, utilizing the right drilling fluid can enhance lubrication and cooling, further improving the drilling process.

Training and experience are also key factors that contribute to the effective use of HDD hole openers. Operators should be well-versed in the operational principles of their equipment, as well as the best practices for handling various subsurface conditions. Investing in training programs can lead to improved safety and efficiency on the job site.

In conclusion, understanding the importance of HDD hole openers and implementing best practices can greatly enhance productivity in industrial drilling operations. By selecting the right tool for the job and ensuring proper maintenance and training, operators can achieve optimal results while minimizing disruptions to the environment and surrounding infrastructure.

In the realm of industrial drilling, particularly in trenchless technology, the HDD (Horizontal Directional Drilling) hole opener plays a critical role. These specialized tools are designed to create larger diameter holes in a variety of subsurface conditions, facilitating the installation of pipelines, cables, and other infrastructure. Understanding the functionality and types of HDD hole openers can help professionals in the field make informed decisions that enhance operational efficiency.

HDD hole openers work by enlarging a pilot hole, which is first drilled using a smaller bit. The hole opener is then attached to a drill string and directed through the pilot hole, effectively expanding its diameter. This process allows for the installation of larger bore pipelines without the need for traditional trenching, which can be both time-consuming and disruptive to the surrounding environment.

There are several types of HDD hole openers available, each designed for specific applications. For instance, roller cone hole openers are ideal for drilling through hard rock formations, while fixed blade hole openers are better suited for softer soils. Understanding the geological conditions of the drilling site is crucial when selecting the appropriate HDD hole opener, as it can significantly impact the drilling performance and overall project success.

In addition to choosing the right type of hole opener, several best practices can help maximize efficiency when using HDD hole openers. First, ensuring that the equipment is well-maintained can reduce downtime and optimize drilling speed. Regular inspections and prompt replacements of worn components are essential for maintaining operational integrity.

Moreover, it's important to monitor drilling parameters, such as torque and pressure, during the drilling process. Adjusting these parameters according to the specific conditions encountered can prevent potential issues, such as excessive wear or equipment failure. Additionally, utilizing the right drilling fluid can enhance lubrication and cooling, further improving the drilling process.

Training and experience are also key factors that contribute to the effective use of HDD hole openers. Operators should be well-versed in the operational principles of their equipment, as well as the best practices for handling various subsurface conditions. Investing in training programs can lead to improved safety and efficiency on the job site.

In conclusion, understanding the importance of HDD hole openers and implementing best practices can greatly enhance productivity in industrial drilling operations. By selecting the right tool for the job and ensuring proper maintenance and training, operators can achieve optimal results while minimizing disruptions to the environment and surrounding infrastructure.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.