Efficient and Reliable Drilling Solutions: Insights into Trenchless Hole Openers

Mar 30,2025

Efficient and Reliable Drilling Solutions: Insights into Trenchless Hole Openers

Table of Contents

- 1. Introduction to Trenchless Hole Openers

- 2. What Are Trenchless Hole Openers?

- 3. Benefits of Using Trenchless Technology

- 4. Applications of Trenchless Hole Openers

- 5. Types of Trenchless Hole Openers

- 6. Choosing the Right Hole Opener for Your Project

- 7. Installation and Operation Tips

- 8. Maintenance and Care for Longevity

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Trenchless Hole Openers

The construction and industrial sectors are constantly evolving, driven by the need for efficient, cost-effective solutions. **Trenchless hole openers** have emerged as a revolutionary technology that allows for the excavation of large holes without the need for extensive surface disruption. This method not only enhances productivity but also minimizes environmental impact, making it a preferred choice for many contractors and project managers.

2. What Are Trenchless Hole Openers?

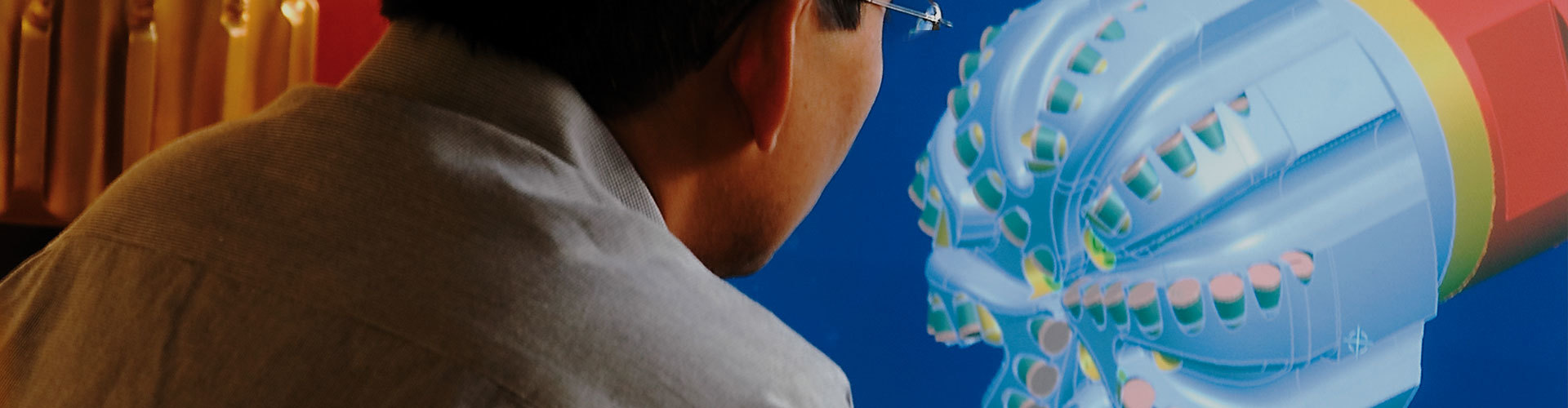

Trenchless hole openers are advanced drilling tools specifically designed for creating large diameter holes underground. Unlike traditional drilling techniques, which often require extensive trenching and excavation, trenchless methods allow operators to install pipes, cables, and other infrastructure beneath the surface with minimal disruption. These tools are commonly used in utility installations, water and sewer lines, and other underground applications.

How Trenchless Hole Openers Work

The operation of a trenchless hole opener typically involves the use of a drilling rig equipped with a specialized hole opener. The drill bit is pushed through the ground, creating a bore that can accommodate various utilities. The technology enables the simultaneous advancement of the hole opener while extracting the cuttings, ensuring a clean and efficient process.

3. Benefits of Using Trenchless Technology

The adoption of trenchless technology for drilling offers several compelling advantages:

Reduced Surface Disruption

Utilizing trenchless hole openers significantly reduces the need for extensive digging, preserving existing landscapes and minimizing the impact on surrounding properties.

Cost-Effectiveness

By decreasing the amount of manual labor and equipment required for traditional excavation methods, trenchless solutions can lead to substantial cost savings in both time and resources.

Increased Safety

Trenchless drilling reduces the risks associated with open excavation, including cave-ins and accidents. The controlled environment allows for safer operations and better management of hazardous materials.

Environmental Benefits

By limiting surface disruption, trenchless technologies help protect local ecosystems and reduce the carbon footprint associated with traditional drilling.

4. Applications of Trenchless Hole Openers

Trenchless hole openers have a wide range of applications across various industries, including:

Utility Installation

They are extensively used for installing underground utilities such as water pipes, gas lines, telecommunications cables, and electrical conduits.

Environmental Remediation

Trenchless technology is essential in environmental projects, allowing for the installation of containment systems and monitoring wells without causing significant surface disturbance.

Mining and Resource Extraction

In mining operations, trenchless hole openers facilitate the extraction of minerals while reducing the environmental impact of surface mining practices.

5. Types of Trenchless Hole Openers

There are various types of trenchless hole openers, each designed for specific applications. Understanding these types is crucial for selecting the best tool for your project.

Fixed Blade Hole Openers

These hole openers feature fixed blades and are ideal for creating consistent, large diameter holes in various soil conditions.

Retractable Hole Openers

Retractable hole openers can be expanded and contracted based on the required hole size, making them versatile for different applications.

Conical Hole Openers

Designed with a conical shape, these hole openers are effective for drilling through hard rock and dense materials, offering superior cutting efficiency.

6. Choosing the Right Hole Opener for Your Project

Selecting the appropriate trenchless hole opener is critical for achieving optimal results. Consider the following factors:

Soil Conditions

Analyze the soil type and density to determine the most suitable hole opener. Soft soils may require different tools compared to hard rock conditions.

Project Specifications

Assess the required diameter and depth of the hole to ensure compatibility with the chosen hole opener.

Budget and Cost

Evaluate your budget constraints and select a hole opener that provides the best balance between cost and performance.

7. Installation and Operation Tips

Proper installation and operation of trenchless hole openers are essential for maximizing efficiency and minimizing downtime.

Pre-Installation Assessment

Conduct a thorough site assessment to identify potential obstacles and understand the underground conditions before commencing drilling.

Equipment Setup

Ensure that the drilling rig is properly calibrated and that all components are in good working order before beginning operations.

Monitoring During Operation

Keep an eye on the drilling process and make adjustments as necessary to maintain efficiency and prevent potential issues.

8. Maintenance and Care for Longevity

Regular maintenance is vital to ensuring the longevity and performance of trenchless hole openers. Follow these best practices:

Routine Inspections

Perform regular inspections to check for wear and tear, ensuring all components function correctly.

Cleaning After Use

Thoroughly clean the hole opener after each use to remove debris and prevent corrosion.

Storage Conditions

Store hole openers in a dry, climate-controlled environment to protect them from environmental damage.

9. Frequently Asked Questions

What is the primary advantage of using trenchless hole openers?

The primary advantage is reduced surface disruption, which minimizes environmental impact and allows for quicker project completion.

Can trenchless hole openers be used in rocky soil?

Yes, certain types of hole openers, specifically designed for hard rock conditions, can effectively drill through rocky soil.

How do I determine the right size of the hole opener for my project?

Consult project specifications, including required diameter and depth, while also considering soil conditions to select the right size.

What maintenance is required for trenchless hole openers?

Regular inspections, cleaning after use, and proper storage are essential for maintaining the performance and longevity of hole openers.

Are trenchless technologies environmentally friendly?

Yes, trenchless technologies significantly reduce surface disruption, preserving ecosystems and minimizing carbon footprints.

10. Conclusion

Trenchless hole openers represent a significant advancement in drilling technology, providing efficient and reliable solutions for various industrial applications. By understanding the types, benefits, and best practices associated with these tools, industry professionals can make informed decisions that enhance project outcomes. Embracing trenchless technology not only improves efficiency but also contributes to more sustainable construction practices. As the demand for innovative drilling solutions grows, trenchless hole openers will continue to play a vital role in shaping the future of underground infrastructure development.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.