Maximizing Performance: Choosing the Right Trenchless Hole Opener

Mar 27,2025

Maximizing Performance: Choosing the Right Trenchless Hole Opener

Table of Contents

- Understanding Trenchless Hole Openers

- The Importance of Choosing the Right Hole Opener

- Key Factors to Consider When Selecting Hole Openers

- Types of Trenchless Hole Openers

- Specific Industry Applications

- Best Practices for Using Hole Openers

- Maintenance and Care of Hole Openers

- Common Issues and Solutions

- Conclusion

- FAQs

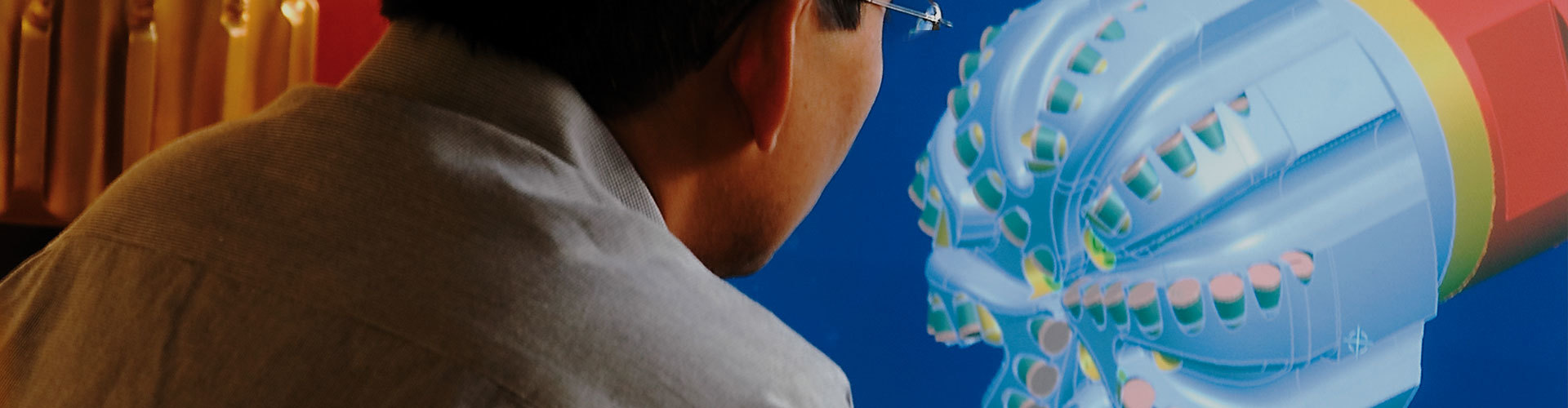

Understanding Trenchless Hole Openers

Trenchless hole openers are specialized tools designed for creating underground pathways without the need for extensive surface disruption. These tools are essential in various applications, including utility installation, pipeline laying, and residential construction projects. By minimizing surface disturbance, trenchless technology enhances urban development while preserving the integrity of the landscape.

The Importance of Choosing the Right Hole Opener

Selecting the appropriate trenchless hole opener significantly impacts the efficiency, cost-effectiveness, and overall success of a project. The right tool can enhance cutting performance, reduce wear and tear, and ensure that the project meets its timeline. Consequently, understanding how to choose the right hole opener is vital for contractors and engineers in the field.

Key Factors to Consider When Selecting Hole Openers

When selecting a trenchless hole opener, several factors must be considered to ensure optimal performance and project success. Below are the crucial elements to evaluate:

Soil Type

The type of soil where the trenchless operation will take place is a significant determinant in choosing a hole opener. Different soil conditions—such as clay, sand, rock, or loam—require specific designs and materials for effective penetration and durability. For instance, rock formations necessitate robust openers with enhanced cutting capabilities, whereas softer soils may allow for more versatile options.

Desired Hole Diameter

The diameter of the hole required for the project also dictates the type of trenchless hole opener selected. Openers come in various sizes, and choosing one that aligns with the intended diameter is crucial for efficiency and minimizing potential issues during drilling.

Project Depth

Project depth is another critical consideration. Deeper projects often demand more specialized equipment capable of handling the increased pressure and potential geological challenges. Selecting an opener designed for deeper applications will help ensure that the operation proceeds smoothly and safely.

Material of Construction

The materials used in manufacturing trenchless hole openers significantly impact their performance and longevity. High-quality materials such as hardened steel or tungsten carbide are preferable as they offer enhanced cutting performance and resistance to wear. Depending on the project demands, it may be advisable to invest in openers made from these durable materials.

Types of Trenchless Hole Openers

Understanding the different types of trenchless hole openers available can assist in making an informed decision. Below are two primary categories:

Roller Bits

Roller bits are designed for efficient cutting through various materials, making them suitable for general drilling applications. They utilize rotating rollers to facilitate penetration and are often favored for their durability and versatility in different soil conditions.

Fixed Blade Openers

Fixed blade openers are characterized by their rigid cutting edges, making them ideal for tougher materials and precise drilling. These openers provide enhanced stability and control, making them suitable for projects requiring high accuracy.

Specific Industry Applications

Trenchless hole openers find applications across various industries, each presenting unique challenges and requirements. Some notable areas include:

- Utilities and Infrastructure: Installation of pipelines for water, gas, and telecommunications.

- Environmental Projects: Installation of monitoring wells and environmental remediation efforts.

- Construction: Foundation work and drainage systems requiring minimal disruption.

Best Practices for Using Hole Openers

To maximize the performance of trenchless hole openers, several best practices should be followed during operation:

- Regularly Inspect Equipment: Frequent inspections help identify wear and tear, enabling timely maintenance.

- Use the Correct Speed and Pressure: Adjusting the drilling parameters to match soil conditions improves efficiency.

- Monitor Soil Conditions: Being aware of changing soil conditions allows for the timely adjustment of techniques.

Maintenance and Care of Hole Openers

Proper maintenance of trenchless hole openers enhances their lifespan and ensures consistent performance. Key maintenance practices include:

- Cleaning: Remove debris and soil accumulation after each use.

- Sharpening: Regularly sharpen cutting edges to maintain efficiency.

- Storage: Store equipment in a dry environment to prevent rust and corrosion.

Common Issues and Solutions

While trenchless hole openers are designed for durability, issues can arise during operation. Here are some common problems and their solutions:

- Excessive Wear: Ensure the correct material and type of opener is chosen for the soil conditions.

- Drilling Resistance: Adjust the speed and pressure settings to better suit the material being drilled.

- Hole Deviation: Regularly check alignment and make adjustments as necessary to maintain the intended path.

Conclusion

Choosing the right trenchless hole opener is a vital aspect of ensuring the success of underground projects. By considering factors such as soil type, desired hole diameter, project depth, and material of construction, we can make informed decisions that enhance performance and efficiency. Understanding the various types of openers available and implementing best practices for use and maintenance further contributes to successful outcomes. With this comprehensive guide, we hope to empower contractors and engineers to maximize their project performance through the informed selection of the right trenchless hole opener.

FAQs

1. What is a trenchless hole opener?

A trenchless hole opener is a specialized drilling tool used to create underground pathways without significant surface disruption, often utilized in utility installation and pipeline laying.

2. How do I determine the right size of hole opener for my project?

The right size depends on the desired hole diameter and the specific requirements of your project. Consider consulting with a professional or manufacturer for recommendations based on your needs.

3. What materials are trenchless hole openers made from?

Common materials include hardened steel and tungsten carbide, which provide durability and resistance to wear.

4. Can I use the same hole opener for different soil types?

While some openers are versatile, it’s generally advisable to choose an opener best suited for the specific soil conditions to ensure efficiency and longevity.

5. How often should I maintain my trenchless hole opener?

Regular maintenance is recommended after each project, including cleaning, inspecting for damage, and sharpening cutting edges as needed.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.