Maximizing Efficiency with PDC Hole Openers in the Industrial Equipment Industry

May 30,2024

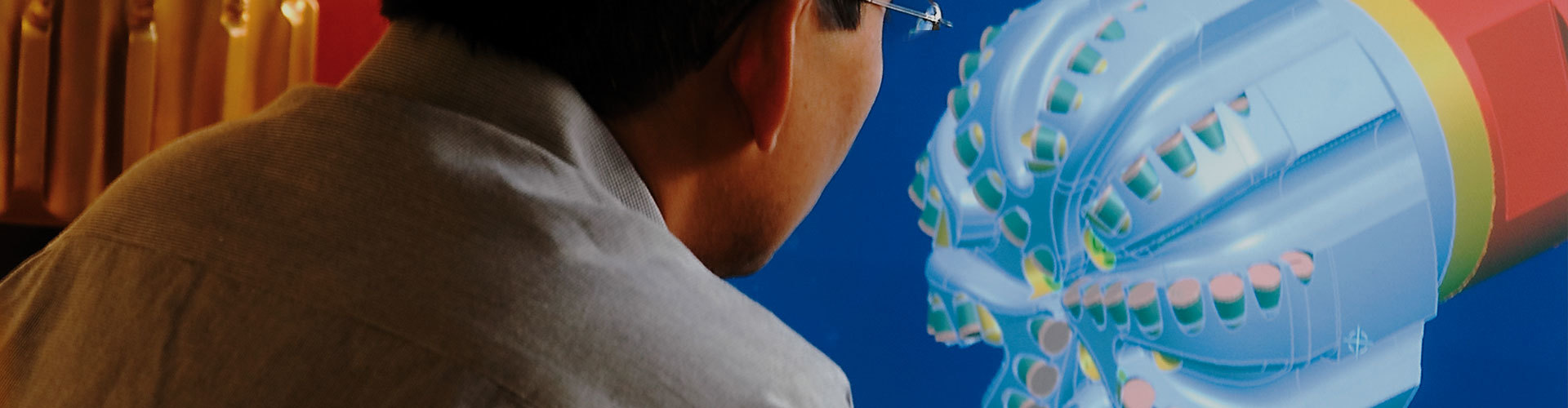

In the field of industrial equipment and components, specifically in the category of cutting tools and fixtures like drill bits, PDC (Polycrystalline Diamond Compact) hole openers play a crucial role in enhancing efficiency and performance. These innovative tools are designed to tackle challenging drilling conditions with precision and reliability.

PDC hole openers are known for their exceptional durability and resistance to wear, making them ideal for tough materials such as hard rocks, concrete, and shale. The use of polycrystalline diamond compacts ensures that the hole openers maintain their sharpness and cutting ability over an extended period, resulting in consistent and high-quality drilling operations.

One of the key advantages of PDC hole openers is their ability to increase drilling speed and efficiency. By incorporating advanced cutting technology and materials, these tools can significantly reduce drilling time and costs while maintaining superior performance. This enhanced efficiency translates to higher productivity and output for industrial applications, ultimately leading to improved profitability.

Furthermore, PDC hole openers are versatile tools that can be customized to meet specific drilling requirements. Whether it's enlarging an existing borehole or creating a new one, these tools offer flexibility and precision to ensure accurate and reliable results. The adaptability of PDC hole openers makes them suitable for a wide range of drilling projects across various industries.

In conclusion, PDC hole openers are essential components in the arsenal of cutting tools and fixtures in the industrial equipment sector. Their advanced technology, durability, and versatility make them indispensable for maximizing efficiency and productivity in drilling operations. By leveraging the benefits of PDC hole openers, businesses can achieve superior results and stay ahead in the competitive market of industrial equipment and components.

PDC hole openers are known for their exceptional durability and resistance to wear, making them ideal for tough materials such as hard rocks, concrete, and shale. The use of polycrystalline diamond compacts ensures that the hole openers maintain their sharpness and cutting ability over an extended period, resulting in consistent and high-quality drilling operations.

One of the key advantages of PDC hole openers is their ability to increase drilling speed and efficiency. By incorporating advanced cutting technology and materials, these tools can significantly reduce drilling time and costs while maintaining superior performance. This enhanced efficiency translates to higher productivity and output for industrial applications, ultimately leading to improved profitability.

Furthermore, PDC hole openers are versatile tools that can be customized to meet specific drilling requirements. Whether it's enlarging an existing borehole or creating a new one, these tools offer flexibility and precision to ensure accurate and reliable results. The adaptability of PDC hole openers makes them suitable for a wide range of drilling projects across various industries.

In conclusion, PDC hole openers are essential components in the arsenal of cutting tools and fixtures in the industrial equipment sector. Their advanced technology, durability, and versatility make them indispensable for maximizing efficiency and productivity in drilling operations. By leveraging the benefits of PDC hole openers, businesses can achieve superior results and stay ahead in the competitive market of industrial equipment and components.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.