Precision Engineering: The Science Behind PDC Hole Opener Innovation

May 29,2024

**Introduction**

Precision engineering plays a crucial role in the development of cutting-edge industrial equipment and components. One such innovation that has been making waves in the industry is the PDC (Polycrystalline Diamond Compact) hole opener. This revolutionary tool has redefined drilling operations and has set new standards for efficiency and performance. In this article, we will delve into the science behind PDC hole opener innovation and explore how it is shaping the landscape of industrial drilling.

**What is Precision Engineering?**

Precision engineering is a specialized branch of engineering that focuses on the design and manufacture of high-precision components and equipment. It involves the use of advanced technologies and techniques to create products with incredibly tight tolerances and superior quality. Precision engineering plays a vital role in various industries, including aerospace, automotive, and oil and gas.

**The Evolution of PDC Hole Openers**

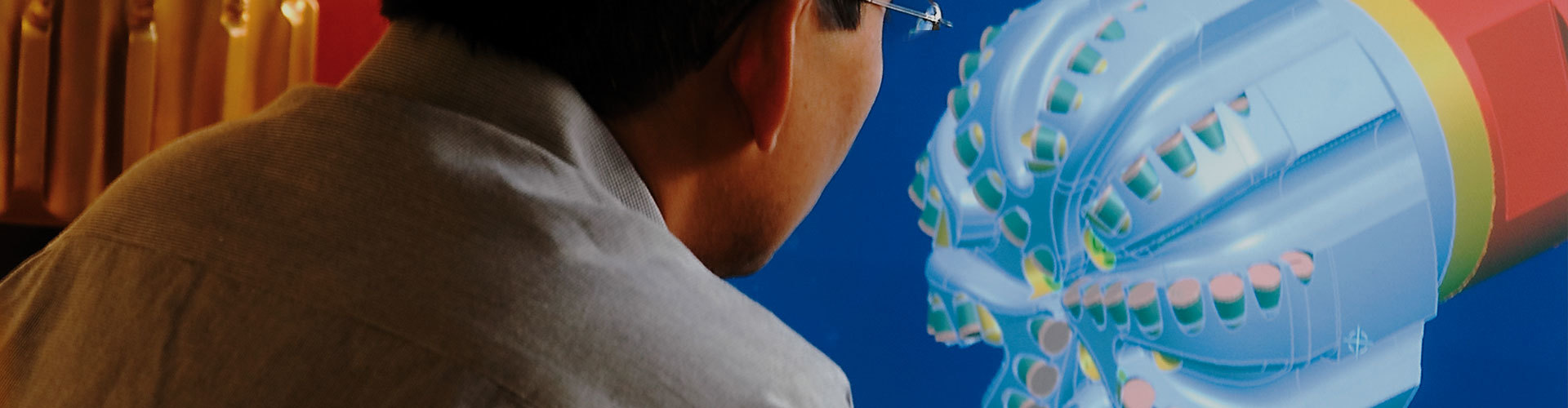

PDC hole openers have come a long way since their inception. Originally designed for use in oil and gas drilling operations, these tools have evolved to become versatile solutions for a wide range of applications. The key innovation behind PDC hole openers lies in their use of polycrystalline diamond cutters, which offer superior durability and wear resistance compared to traditional materials.

**The Science Behind PDC Hole Opener Innovation**

The success of PDC hole openers can be attributed to the meticulous engineering and design that goes into their production. These tools are precision-crafted to ensure optimal performance and longevity in the most demanding drilling conditions. The use of polycrystalline diamond cutters allows PDC hole openers to maintain sharpness and cutting efficiency over extended periods, resulting in faster and more efficient drilling operations.

**Benefits of PDC Hole Openers**

The adoption of PDC hole openers has brought about a multitude of benefits for industries that rely on drilling operations. These tools offer increased durability, reduced downtime, and improved drilling efficiency, leading to significant cost savings and enhanced productivity. The precision engineering behind PDC hole openers ensures consistent performance and reliability, making them a preferred choice for demanding applications.

**FAQs**

1. **What sets PDC hole openers apart from traditional drilling tools?**

PDC hole openers offer superior durability and wear resistance due to their use of polycrystalline diamond cutters, making them ideal for challenging drilling conditions.

2. **How are PDC hole openers manufactured?**

PDC hole openers undergo a rigorous manufacturing process that involves precision engineering techniques to ensure optimal performance and longevity.

3. **What industries can benefit from using PDC hole openers?**

PDC hole openers are versatile tools that can be used in a wide range of industries, including oil and gas, mining, and construction.

4. **How do PDC hole openers improve drilling efficiency?**

The sharpness and cutting efficiency of polycrystalline diamond cutters allow PDC hole openers to drill faster and more efficiently than traditional tools.

5. **Are PDC hole openers cost-effective in the long run?**

Yes, the durability and consistent performance of PDC hole openers result in significant cost savings and increased productivity over time.

**Conclusion**

In conclusion, the science behind PDC hole opener innovation represents a significant advancement in precision engineering. These groundbreaking tools have revolutionized drilling operations and have set new standards for efficiency and performance. With their superior durability and cutting-edge design, PDC hole openers are shaping the future of industrial equipment and components, paving the way for improved productivity and cost savings in a wide range of industries.

Precision engineering plays a crucial role in the development of cutting-edge industrial equipment and components. One such innovation that has been making waves in the industry is the PDC (Polycrystalline Diamond Compact) hole opener. This revolutionary tool has redefined drilling operations and has set new standards for efficiency and performance. In this article, we will delve into the science behind PDC hole opener innovation and explore how it is shaping the landscape of industrial drilling.

**What is Precision Engineering?**

Precision engineering is a specialized branch of engineering that focuses on the design and manufacture of high-precision components and equipment. It involves the use of advanced technologies and techniques to create products with incredibly tight tolerances and superior quality. Precision engineering plays a vital role in various industries, including aerospace, automotive, and oil and gas.

**The Evolution of PDC Hole Openers**

PDC hole openers have come a long way since their inception. Originally designed for use in oil and gas drilling operations, these tools have evolved to become versatile solutions for a wide range of applications. The key innovation behind PDC hole openers lies in their use of polycrystalline diamond cutters, which offer superior durability and wear resistance compared to traditional materials.

**The Science Behind PDC Hole Opener Innovation**

The success of PDC hole openers can be attributed to the meticulous engineering and design that goes into their production. These tools are precision-crafted to ensure optimal performance and longevity in the most demanding drilling conditions. The use of polycrystalline diamond cutters allows PDC hole openers to maintain sharpness and cutting efficiency over extended periods, resulting in faster and more efficient drilling operations.

**Benefits of PDC Hole Openers**

The adoption of PDC hole openers has brought about a multitude of benefits for industries that rely on drilling operations. These tools offer increased durability, reduced downtime, and improved drilling efficiency, leading to significant cost savings and enhanced productivity. The precision engineering behind PDC hole openers ensures consistent performance and reliability, making them a preferred choice for demanding applications.

**FAQs**

1. **What sets PDC hole openers apart from traditional drilling tools?**

PDC hole openers offer superior durability and wear resistance due to their use of polycrystalline diamond cutters, making them ideal for challenging drilling conditions.

2. **How are PDC hole openers manufactured?**

PDC hole openers undergo a rigorous manufacturing process that involves precision engineering techniques to ensure optimal performance and longevity.

3. **What industries can benefit from using PDC hole openers?**

PDC hole openers are versatile tools that can be used in a wide range of industries, including oil and gas, mining, and construction.

4. **How do PDC hole openers improve drilling efficiency?**

The sharpness and cutting efficiency of polycrystalline diamond cutters allow PDC hole openers to drill faster and more efficiently than traditional tools.

5. **Are PDC hole openers cost-effective in the long run?**

Yes, the durability and consistent performance of PDC hole openers result in significant cost savings and increased productivity over time.

**Conclusion**

In conclusion, the science behind PDC hole opener innovation represents a significant advancement in precision engineering. These groundbreaking tools have revolutionized drilling operations and have set new standards for efficiency and performance. With their superior durability and cutting-edge design, PDC hole openers are shaping the future of industrial equipment and components, paving the way for improved productivity and cost savings in a wide range of industries.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.