How Steel Tooth Reaming Drill Bit Boosts Industrial Productivity

Jan 29,2025

How Steel Tooth Reaming Drill Bit Boosts Industrial Productivity

Table of Contents

- Introduction to Steel Tooth Reaming Drill Bits

- Key Benefits of Steel Tooth Reaming Drill Bits

- Applications of Steel Tooth Reaming Drill Bits in Industry

- Design Features of Steel Tooth Reaming Drill Bits

- Material Composition and Its Importance

- Performance Metrics: How They Enhance Productivity

- How to Select the Right Steel Tooth Reaming Drill Bit

- Maintenance Tips for Longevity and Efficiency

- Conclusion

- FAQs About Steel Tooth Reaming Drill Bits

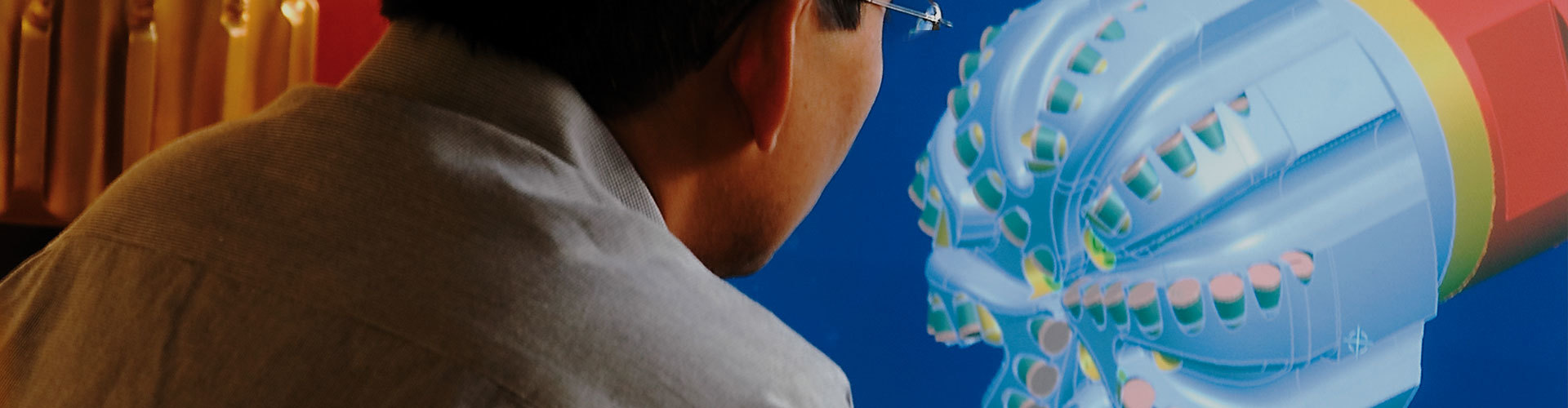

Introduction to Steel Tooth Reaming Drill Bits

Steel tooth reaming drill bits are engineered tools designed for high-performance drilling operations in various industrial fields. They play a critical role in enhancing productivity by ensuring precise hole dimensions and improving overall operational efficiency. The intricate design of these drill bits allows for effective material removal, enabling businesses to operate at higher speeds and reduced costs.

Key Benefits of Steel Tooth Reaming Drill Bits

Steel tooth reaming drill bits offer numerous advantages that contribute to increased productivity in industrial settings. Some of the most notable benefits include:

1. Enhanced Durability

Crafted from high-quality steel, these drill bits are designed to withstand intense drilling conditions. Their robust construction minimizes wear and tear, leading to a longer lifespan.

2. Improved Precision

The precision-engineered design ensures that drilled holes meet exact specifications, reducing the need for rework and increasing the quality of the finished product.

3. Higher Speeds and Feed Rates

Steel tooth reaming drill bits allow for faster drilling speeds due to their efficient cutting geometry. This capability helps industries complete projects more quickly, thus enhancing overall productivity.

4. Versatility in Applications

These drill bits can be used across various materials, making them a versatile choice for different industrial applications, from oil and gas drilling to construction.

5. Cost-Effectiveness

While the initial investment in steel tooth reaming drill bits may be higher, their durability and efficiency lead to significant cost savings in the long run through reduced downtime and maintenance.

Applications of Steel Tooth Reaming Drill Bits in Industry

The versatility of steel tooth reaming drill bits makes them suitable for a range of applications across multiple industries. Some key sectors include:

1. Oil and Gas Industry

In the oil and gas sector, these drill bits are crucial for creating wellbores that are both precise and efficient. Their ability to handle tough geological formations makes them a preferred choice in drilling applications.

2. Construction

Steel tooth reaming drill bits are extensively used in construction projects for drilling anchor holes, reaming existing holes, and preparing surfaces for various fittings.

3. Mining

In mining operations, these drill bits assist in creating access holes and extraction points, ensuring that the drilling process is both effective and safe.

4. Manufacturing

Manufacturers utilize steel tooth reaming drill bits to ensure that components fit together correctly and function as intended, which is essential for high-quality production.

Design Features of Steel Tooth Reaming Drill Bits

The design of steel tooth reaming drill bits is pivotal in determining their performance and efficiency. Key design features include:

1. Tooth Geometry

The arrangement and shape of the teeth on the drill bit are crucial for effective cutting. A well-designed tooth geometry allows for reduced friction and optimal material removal.

2. Flute Design

The flutes on the drill bit aid in the removal of chips and debris from the drilling site. A thoughtful flute design enhances the bit's ability to maintain a clear cutting path.

3. Shank Configuration

The shank of the drill bit is designed to fit securely in the drilling equipment, ensuring stability during operation and reducing vibrations.

Material Composition and Its Importance

The choice of material in steel tooth reaming drill bits significantly impacts their performance. Typically made from high-carbon steel or alloy steel, the material influences:

1. Hardness

A harder material allows the drill bits to maintain their sharpness longer and resist wear, ultimately enhancing their lifespan.

2. Toughness

The toughness of the material helps the drill bits withstand the stress of drilling through tough materials without fracturing.

3. Heat Resistance

High-quality steel tooth reaming drill bits are engineered to resist heat buildup during drilling, which is essential for maintaining performance and preventing failure.

Performance Metrics: How They Enhance Productivity

Measuring the performance of steel tooth reaming drill bits involves several key metrics that contribute directly to productivity:

1. Rate of Penetration (ROP)

The ROP indicates how quickly a drill bit can penetrate a material. Higher ROP translates to faster project completion and reduced labor costs.

2. Tool Life

A longer tool life means fewer replacements, lower maintenance costs, and less downtime. Steel tooth reaming drill bits are designed to maximize tool life through their robust construction.

3. Surface Finish

The quality of the finished hole can impact subsequent operations. A better surface finish reduces the need for additional machining, saving time and resources.

How to Select the Right Steel Tooth Reaming Drill Bit

Selecting the appropriate steel tooth reaming drill bit is crucial for optimizing productivity. Consider the following factors:

1. Application Requirements

Understand the specific requirements of your application, including the type of material being drilled, the desired hole size, and the thickness of the material.

2. Bit Size and Geometry

Choose a bit size that aligns with your operational needs. The geometry of the bit should match the drilling conditions to ensure efficient performance.

3. Manufacturer Reputation

Opt for drill bits from reputable manufacturers known for quality and performance. This choice can significantly influence the outcome of your drilling operations.

Maintenance Tips for Longevity and Efficiency

Proper maintenance of steel tooth reaming drill bits can enhance their performance and extend their lifespan. Here are some essential tips:

1. Regular Inspection

Conduct regular inspections to check for wear and damage. Early detection of issues can prevent further complications.

2. Cleaning

Keep the drill bits clean by removing any debris and build-up after use. This practice helps maintain optimal cutting performance.

3. Storage

Store drill bits in a dry, cool place to prevent corrosion and damage. Proper storage can significantly prolong their lifespan.

Conclusion

Steel tooth reaming drill bits are invaluable tools that significantly enhance productivity in various industrial applications. With their robust design, versatile applications, and superior performance metrics, these drill bits enable industries to accelerate their operations while maintaining high-quality standards. By understanding the benefits, selecting the right tools, and adhering to maintenance best practices, businesses can fully leverage the capabilities of steel tooth reaming drill bits, ultimately leading to improved productivity and cost-effectiveness.

FAQs About Steel Tooth Reaming Drill Bits

1. What are steel tooth reaming drill bits used for?

Steel tooth reaming drill bits are used for drilling precise holes in various materials, including metals and concrete, across industries such as oil and gas, construction, and manufacturing.

2. How do I determine the right size for a steel tooth reaming drill bit?

To determine the right size, consider the specific requirements of your project, including the material type and the desired hole dimensions.

3. Can steel tooth reaming drill bits be used in tough materials?

Yes, steel tooth reaming drill bits are designed to handle tough materials and challenging drilling conditions, making them a reliable choice for demanding applications.

4. How can I prolong the life of my steel tooth reaming drill bits?

Regular inspection, proper cleaning, and correct storage are essential practices to prolong the life of your drill bits.

5. Are there specific manufacturers known for high-quality steel tooth reaming drill bits?

Yes, several manufacturers are known for producing high-quality steel tooth reaming drill bits. It's advisable to research and choose reputable brands based on reviews and industry standards.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.