Choosing the Right Core Barrel Roller Cone for Your Drilling Needs

Mar 15,2025

Choosing the Right Core Barrel Roller Cone for Your Drilling Needs

Table of Contents

- What is a Core Barrel Roller Cone?

- Importance of Core Barrel Roller Cones in Drilling

- Types of Core Barrel Roller Cones

- Factors to Consider When Choosing Core Barrel Roller Cones

- Material Options for Core Barrel Roller Cones

- Design Features of Core Barrel Roller Cones

- Operational Efficiency of Core Barrel Roller Cones

- Cost-Effectiveness and Value

- Frequently Asked Questions

- Conclusion

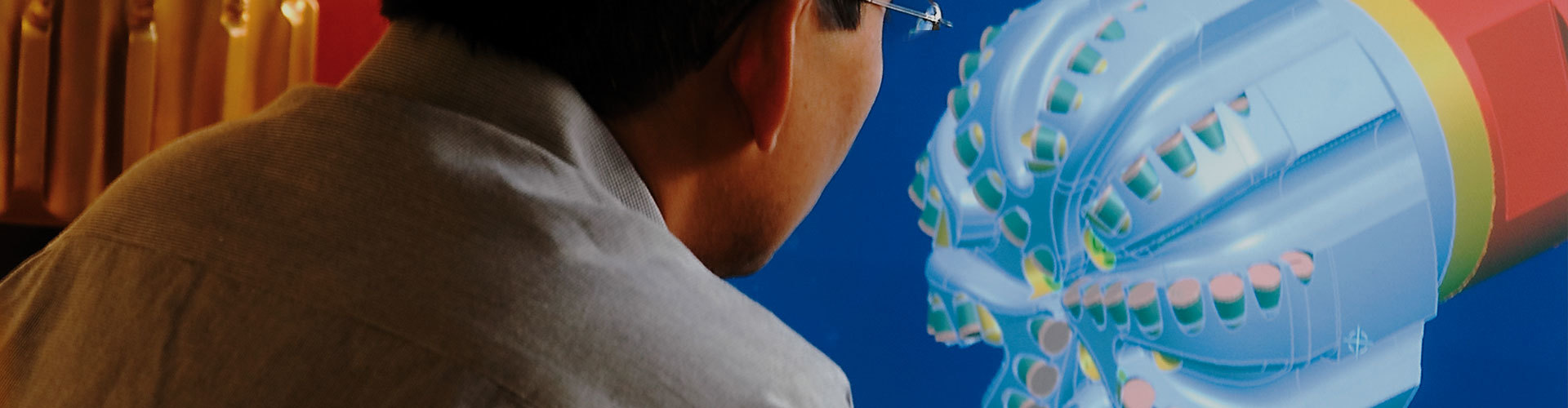

What is a Core Barrel Roller Cone?

A core barrel roller cone is a specialized drilling tool designed to extract core samples from various geological formations. The roller cone mechanism allows for efficient penetration and extraction while maintaining the integrity of the core sample. These tools are crucial in industries such as mining, construction, and geotechnical investigations, where accurate geological data is essential for project planning and execution.

Importance of Core Barrel Roller Cones in Drilling

The significance of core barrel roller cones cannot be understated. They play a critical role in obtaining high-quality core samples, which are essential for understanding the subsurface geology. These samples can inform crucial decisions about resource extraction, environmental impact, and structural integrity. Furthermore, using the right core barrel roller cone ensures efficient drilling, reducing downtime and increasing productivity.

Types of Core Barrel Roller Cones

Core barrel roller cones come in various types, each tailored to specific drilling requirements. The main categories include:

- Tricone Roller Cones: These are widely used in soft to hard formations, featuring three rotating cones that provide optimal penetration and core recovery.

- Polycrystalline Diamond Compact (PDC) Bits: Ideal for hard rock drilling, PDC bits provide longevity and efficiency due to their diamond-coated cutting edges.

- Diamond Core Bits: These bits are specifically designed for core drilling in hard materials, offering superior cutting capabilities and core retention.

Factors to Consider When Choosing Core Barrel Roller Cones

Selecting the right core barrel roller cone involves considering several factors to ensure optimal performance:

1. Geological Formation

The type of rock or soil you are drilling into directly influences the choice of core barrel roller cone. Soft formations may require different tools compared to hard rock.

2. Core Recovery Rate

Assessing the core recovery rate is essential for determining the effectiveness of your drilling operation. Higher recovery rates mean better sample quality.

3. Drilling Depth

The intended drilling depth can dictate the type of core barrel roller cone required. Certain cones are designed to withstand greater pressures at deeper levels.

4. Budget Constraints

Cost plays a significant role in decision-making. It's essential to balance quality and performance with budgetary limitations.

Material Options for Core Barrel Roller Cones

The materials used in core barrel roller cones significantly impact their performance and durability. Common materials include:

- Steel: A traditional choice known for its durability and cost-effectiveness, steel is suitable for various drilling applications.

- Cobalt: Often used for its hardness and resistance to wear, cobalt is ideal for challenging drilling environments.

- Diamond: Used in premium bits, diamond materials offer superior cutting capabilities and longevity, especially in hard rock formations.

Design Features of Core Barrel Roller Cones

The design of core barrel roller cones affects their performance and effectiveness in the field. Key design features to consider include:

1. Cone Configuration

The arrangement and shape of the cones can influence penetration rates and core quality. Some designs prioritize stability, while others focus on speed.

2. Bearing Design

High-quality bearings reduce friction and improve the lifespan of the core barrel roller cone, allowing for smoother operation in challenging conditions.

Operational Efficiency of Core Barrel Roller Cones

Operational efficiency is crucial in drilling projects, as it directly correlates to time and cost savings. Factors contributing to efficiency include:

- Speed of Penetration: The faster a core barrel roller cone can penetrate, the more efficient the drilling operation.

- Torque Requirements: Lower torque requirements reduce the strain on drilling equipment, leading to longer operational life.

Cost-Effectiveness and Value

While it might be tempting to choose the cheapest option available, it’s essential to consider the long-term value of your investment. Factors influencing cost-effectiveness include:

- Longevity: Higher upfront costs for durable materials can lead to lower replacement rates and overall cost savings.

- Performance: Tools that perform well contribute to increased productivity, allowing for quicker project completion and reduced labor costs.

Frequently Asked Questions

1. What is the best core barrel roller cone for soft rock?

For soft rock, tricone roller cones are typically preferred due to their effectiveness in penetration and core recovery.

2. How do I know if my core barrel roller cone is worn out?

Signs of wear include reduced core recovery rates, increased drilling resistance, and visible damage to the cutting edges of the cones.

3. Can I use the same core barrel roller cone for different formations?

While some cones may perform adequately across various formations, it’s advisable to use specialized tools for each specific geological condition for optimal results.

4. How often should I replace my core barrel roller cone?

The replacement frequency depends on various factors, including the material being drilled and the operational conditions. Regular inspections can help determine when replacement is necessary.

5. What maintenance is required for core barrel roller cones?

Routine maintenance includes cleaning, lubrication, and inspections for wear and tear. Proper care can significantly extend the lifespan of your equipment.

Conclusion

Choosing the right core barrel roller cone for your drilling needs is a critical decision that can influence the success of your projects. By considering factors such as geological formations, core recovery rates, and material options, you can make an informed choice that balances performance and cost. Investing in quality tools tailored to your specific requirements will not only enhance operational efficiency but also ensure the integrity of your core samples. Ultimately, the right core barrel roller cone can lead to significant time and cost savings while providing the data necessary for informed decision-making in your drilling operations.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.