Understanding Tricone Rock Drilling Bits: A Comprehensive Guide for Industry Professionals

Nov 22,2024

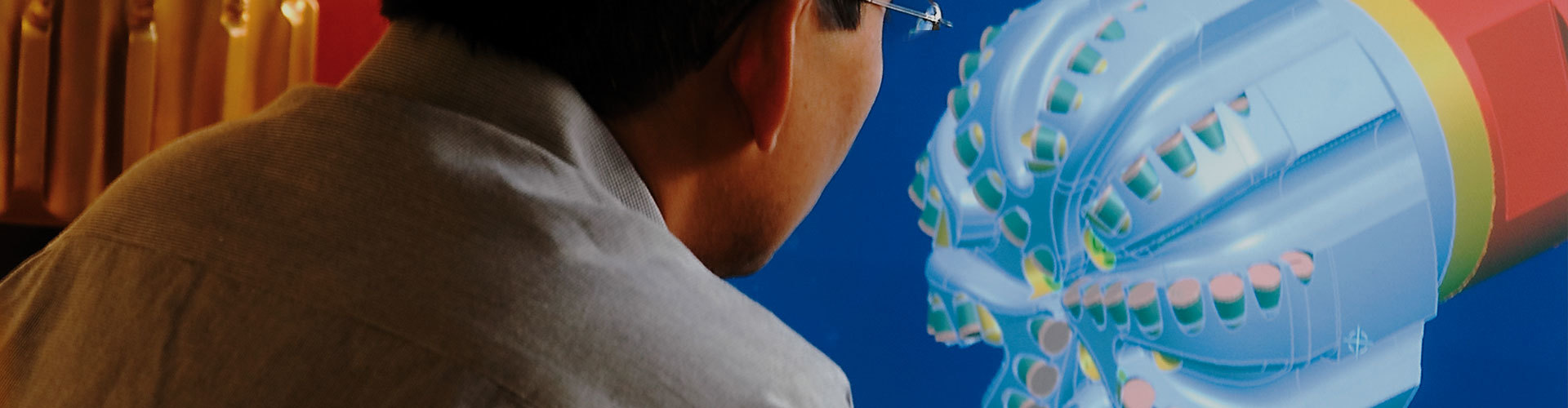

Tricone rock drilling bits are pivotal components in the field of industrial drilling, particularly utilized in oil, gas, and mineral exploration. These bits are characterized by their three rotating cones, each fitted with tungsten carbide teeth or inserts designed to efficiently penetrate hard rock formations. Understanding the functionality and design of tricone bits is crucial for professionals in the drilling industry, as it directly impacts the efficiency and effectiveness of drilling operations.

The primary advantage of tricone bits lies in their ability to drill through a variety of geological formations. The three cones rotate independently, allowing for a more aggressive cutting action compared to single-cone bits. This unique design enables tricone bits to adapt to different rock types, making them ideal for diverse drilling environments. Moreover, the bit's structure facilitates the removal of cuttings, which is critical for maintaining drilling efficiency and preventing blockages.

When selecting a tricone rock drilling bit, several factors must be considered. The type of formation to be drilled is paramount; soft formations may require bits with softer teeth, while hard, abrasive rocks necessitate more robust, wear-resistant materials. Additionally, the size and configuration of the bit can influence the rate of penetration and overall performance. Professionals should assess these parameters to ensure optimal bit selection.

Tricone bits come in various designs, including standard, hybrid, and PDC (polycrystalline diamond compact) options. Each design serves specific purposes and is suited for different drilling conditions. For instance, hybrid bits combine the advantages of tricone and PDC technologies, offering enhanced durability and cutting efficiency. Understanding these variations helps professionals make informed decisions regarding equipment for specific projects.

Furthermore, the maintenance and care of tricone bits are vital for prolonging their lifespan. Regular inspections and timely replacements can prevent performance degradation and reduce operational downtime. Professionals should implement a robust maintenance schedule to ensure that their drilling equipment remains in peak condition.

In conclusion, tricone rock drilling bits are essential tools in the drilling industry, offering versatility and efficiency across various applications. By understanding their design, functionality, and maintenance requirements, industry professionals can optimize their drilling operations, reduce costs, and achieve better results. As drilling projects become increasingly complex, staying informed about advancements in tricone bit technology will continue to be an essential aspect of professional development in this sector.

The primary advantage of tricone bits lies in their ability to drill through a variety of geological formations. The three cones rotate independently, allowing for a more aggressive cutting action compared to single-cone bits. This unique design enables tricone bits to adapt to different rock types, making them ideal for diverse drilling environments. Moreover, the bit's structure facilitates the removal of cuttings, which is critical for maintaining drilling efficiency and preventing blockages.

When selecting a tricone rock drilling bit, several factors must be considered. The type of formation to be drilled is paramount; soft formations may require bits with softer teeth, while hard, abrasive rocks necessitate more robust, wear-resistant materials. Additionally, the size and configuration of the bit can influence the rate of penetration and overall performance. Professionals should assess these parameters to ensure optimal bit selection.

Tricone bits come in various designs, including standard, hybrid, and PDC (polycrystalline diamond compact) options. Each design serves specific purposes and is suited for different drilling conditions. For instance, hybrid bits combine the advantages of tricone and PDC technologies, offering enhanced durability and cutting efficiency. Understanding these variations helps professionals make informed decisions regarding equipment for specific projects.

Furthermore, the maintenance and care of tricone bits are vital for prolonging their lifespan. Regular inspections and timely replacements can prevent performance degradation and reduce operational downtime. Professionals should implement a robust maintenance schedule to ensure that their drilling equipment remains in peak condition.

In conclusion, tricone rock drilling bits are essential tools in the drilling industry, offering versatility and efficiency across various applications. By understanding their design, functionality, and maintenance requirements, industry professionals can optimize their drilling operations, reduce costs, and achieve better results. As drilling projects become increasingly complex, staying informed about advancements in tricone bit technology will continue to be an essential aspect of professional development in this sector.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.