Maximizing Efficiency: Tips for Properly Using Stepped Drag Bits

Jun 26,2024

**Introduction**

In the world of industrial equipment and components, the proper use of tools like stepped drag bits is crucial for maximizing efficiency and achieving optimal results. These specialized tools are designed to provide precision drilling capabilities, making them essential for various applications in the manufacturing and construction industries. In this article, we will explore the best practices for using stepped drag bits to improve performance, increase productivity, and streamline operations.

**Understanding Stepped Drag Bits**

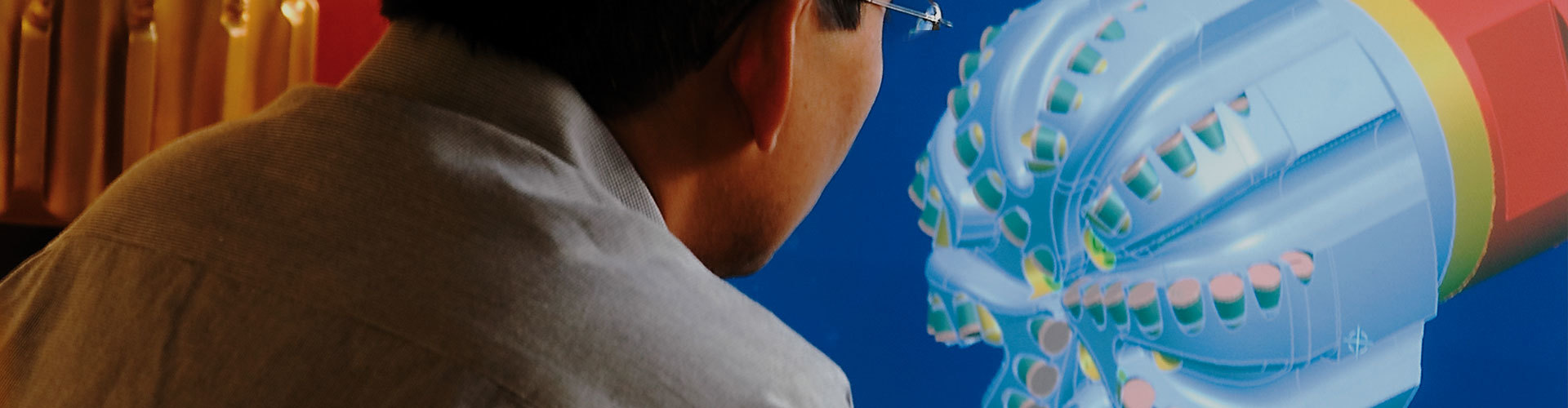

Stepped drag bits are cutting tools used in drilling operations to create holes in various materials, including metal, wood, and concrete. These bits feature a stepped design with multiple cutting edges that allow for efficient material removal and precise hole formation. By utilizing the unique design of stepped drag bits, operators can achieve faster drilling speeds and higher levels of accuracy compared to traditional drill bits.

**Optimizing Performance**

To maximize the efficiency of stepped drag bits, it is essential to follow a few key tips and strategies. Firstly, ensure that the bit is properly sharpened and maintained to maintain optimal cutting performance. Regular maintenance and sharpening will help prolong the lifespan of the bit and ensure consistent results during drilling operations.

**Increasing Productivity**

In addition to proper maintenance, operators can increase productivity by utilizing the correct drilling techniques and strategies. When using stepped drag bits, it is essential to choose the appropriate speed and feed rates to optimize cutting efficiency. By adjusting these factors based on the material being drilled, operators can achieve faster drilling speeds and reduce overall production time.

**Achieving Superior Results**

By implementing the tips and strategies outlined in this article, operators can achieve superior results when using stepped drag bits in drilling operations. From increased productivity to improved performance, these specialized tools can help streamline operations and enhance overall efficiency in industrial settings. By following best practices and utilizing the unique capabilities of stepped drag bits, operators can take their drilling operations to the next level.

**FAQs**

1. How often should stepped drag bits be sharpened?

- Stepped drag bits should be sharpened regularly to maintain optimal cutting performance.

2. What are the benefits of using stepped drag bits?

- Stepped drag bits offer faster drilling speeds and higher levels of accuracy compared to traditional drill bits.

3. How can operators increase productivity when using stepped drag bits?

- By adjusting speed and feed rates based on the material being drilled, operators can optimize cutting efficiency and increase productivity.

4. What are some common applications for stepped drag bits?

- Stepped drag bits are commonly used in metalworking, woodworking, and construction applications for precision drilling.

5. What is the lifespan of a typical stepped drag bit?

- The lifespan of a stepped drag bit can vary depending on usage and maintenance, but regular sharpening and proper care can help prolong its lifespan.

**Conclusion**

In conclusion, maximizing efficiency when using stepped drag bits in industrial equipment and components is essential for achieving superior results and streamlining operations. By following the expert tips and strategies outlined in this article, operators can optimize performance, increase productivity, and achieve superior results in their drilling operations. With proper maintenance, correct drilling techniques, and a focus on best practices, operators can take full advantage of the unique capabilities of stepped drag bits and elevate their drilling operations to new heights.

In the world of industrial equipment and components, the proper use of tools like stepped drag bits is crucial for maximizing efficiency and achieving optimal results. These specialized tools are designed to provide precision drilling capabilities, making them essential for various applications in the manufacturing and construction industries. In this article, we will explore the best practices for using stepped drag bits to improve performance, increase productivity, and streamline operations.

**Understanding Stepped Drag Bits**

Stepped drag bits are cutting tools used in drilling operations to create holes in various materials, including metal, wood, and concrete. These bits feature a stepped design with multiple cutting edges that allow for efficient material removal and precise hole formation. By utilizing the unique design of stepped drag bits, operators can achieve faster drilling speeds and higher levels of accuracy compared to traditional drill bits.

**Optimizing Performance**

To maximize the efficiency of stepped drag bits, it is essential to follow a few key tips and strategies. Firstly, ensure that the bit is properly sharpened and maintained to maintain optimal cutting performance. Regular maintenance and sharpening will help prolong the lifespan of the bit and ensure consistent results during drilling operations.

**Increasing Productivity**

In addition to proper maintenance, operators can increase productivity by utilizing the correct drilling techniques and strategies. When using stepped drag bits, it is essential to choose the appropriate speed and feed rates to optimize cutting efficiency. By adjusting these factors based on the material being drilled, operators can achieve faster drilling speeds and reduce overall production time.

**Achieving Superior Results**

By implementing the tips and strategies outlined in this article, operators can achieve superior results when using stepped drag bits in drilling operations. From increased productivity to improved performance, these specialized tools can help streamline operations and enhance overall efficiency in industrial settings. By following best practices and utilizing the unique capabilities of stepped drag bits, operators can take their drilling operations to the next level.

**FAQs**

1. How often should stepped drag bits be sharpened?

- Stepped drag bits should be sharpened regularly to maintain optimal cutting performance.

2. What are the benefits of using stepped drag bits?

- Stepped drag bits offer faster drilling speeds and higher levels of accuracy compared to traditional drill bits.

3. How can operators increase productivity when using stepped drag bits?

- By adjusting speed and feed rates based on the material being drilled, operators can optimize cutting efficiency and increase productivity.

4. What are some common applications for stepped drag bits?

- Stepped drag bits are commonly used in metalworking, woodworking, and construction applications for precision drilling.

5. What is the lifespan of a typical stepped drag bit?

- The lifespan of a stepped drag bit can vary depending on usage and maintenance, but regular sharpening and proper care can help prolong its lifespan.

**Conclusion**

In conclusion, maximizing efficiency when using stepped drag bits in industrial equipment and components is essential for achieving superior results and streamlining operations. By following the expert tips and strategies outlined in this article, operators can optimize performance, increase productivity, and achieve superior results in their drilling operations. With proper maintenance, correct drilling techniques, and a focus on best practices, operators can take full advantage of the unique capabilities of stepped drag bits and elevate their drilling operations to new heights.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.