Maximize Productivity with Tungsten Carbide Insert Tricone Bit

Dec 31,2023

Table of Contents:

1. Introduction

2. Understanding Tungsten Carbide Insert Tricone Bit

3. Advantages of Tungsten Carbide Insert Tricone Bit

4. Application Areas for Tungsten Carbide Insert Tricone Bit

5. Factors Influencing Productivity with Tungsten Carbide Insert Tricone Bit

6. Frequently Asked Questions (FAQs)

7. Conclusion

1. Introduction

In the realm of industrial equipment and component manufacturing, efficiency and productivity play a crucial role. This article explores the benefits of utilizing Tungsten Carbide Insert Tricone Bit in maximizing productivity. By delving into the features and applications of this innovative tool, we aim to provide valuable insights for manufacturers seeking to optimize their efficiency.

2. Understanding Tungsten Carbide Insert Tricone Bit

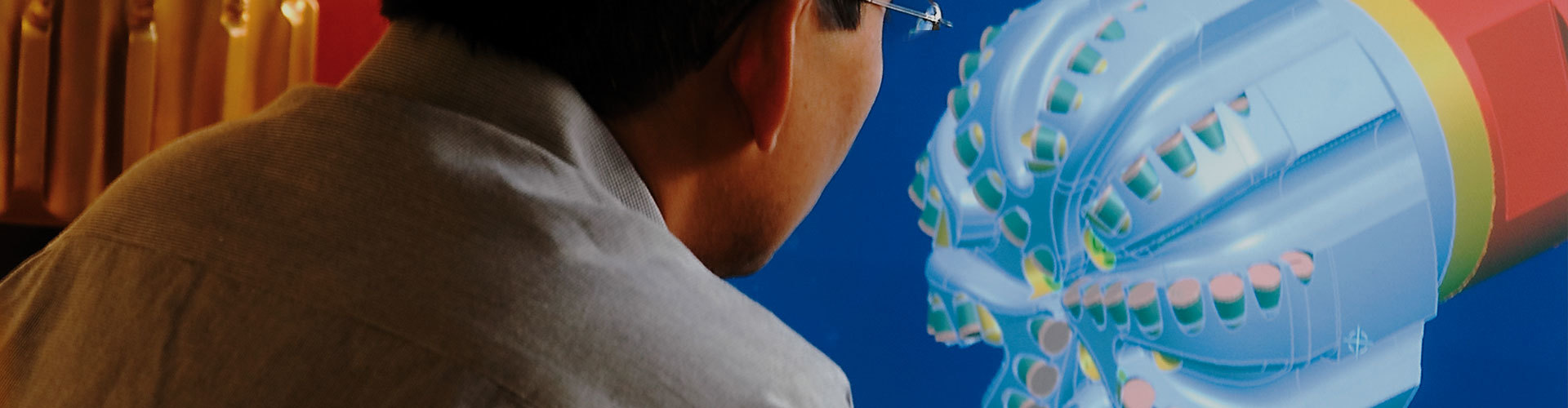

Tungsten Carbide Insert Tricone Bit is a cutting tool widely used in the manufacturing industry. It comprises three rotating cones, each equipped with durable tungsten carbide inserts. These inserts ensure superior durability, high resistance to wear and tear, and excellent cutting performance. With its robust design and precise engineering, the Tungsten Carbide Insert Tricone Bit offers manufacturers a reliable solution for their machining needs.

3. Advantages of Tungsten Carbide Insert Tricone Bit

3.1 Exceptional Durability: The tungsten carbide inserts in the Tricone Bit enhance its durability, making it highly resistant to wear and tear. This longevity ensures extended tool life and minimizes downtime for replacement or maintenance.

3.2 Enhanced Cutting Performance: The precise engineering of Tungsten Carbide Insert Tricone Bit enables it to deliver exceptional cutting performance. Its sharp edges and effective chip evacuation system result in smooth and efficient machining, reducing material wastage and increasing overall productivity.

3.3 Versatility: Tungsten Carbide Insert Tricone Bit is compatible with various materials, including steels, alloys, and composites. This versatility enables manufacturers to utilize the Tricone Bit across a wide range of applications, further enhancing productivity.

4. Application Areas for Tungsten Carbide Insert Tricone Bit

4.1 Metalworking: Tungsten Carbide Insert Tricone Bit finds immense utility in metalworking processes, such as drilling, milling, and turning. Its exceptional cutting performance and durability make it an ideal choice for machining various metals, including stainless steel, aluminum, and cast iron.

4.2 Woodworking: The Tricone Bit is also suitable for woodworking applications. Whether it's creating intricate designs or drilling holes, Tungsten Carbide Insert Tricone Bit offers precision and efficiency, contributing to increased productivity in the woodworking industry.

4.3 Composite Materials: Composite materials, such as fiberglass and carbon fiber, pose unique challenges during machining. Tungsten Carbide Insert Tricone Bit's robust design and cutting capabilities make it an excellent choice for working with composite materials, maximizing productivity while ensuring quality results.

5. Factors Influencing Productivity with Tungsten Carbide Insert Tricone Bit

5.1 Tool Selection: Choosing the right Tungsten Carbide Insert Tricone Bit for specific applications is essential to maximize productivity. Understanding the material properties, cutting requirements, and operating conditions enables manufacturers to select the most suitable tool, ensuring optimal performance.

5.2 Cutting Parameters: Adjusting cutting parameters, including cutting speed, feed rate, and depth of cut, can significantly impact productivity. Optimizing these parameters based on the material being machined and the desired outcome can enhance efficiency and overall productivity.

5.3 Tool Maintenance: Regular maintenance and inspection of Tungsten Carbide Insert Tricone Bit are crucial to ensure peak performance. Cleaning, sharpening, and replacing worn-out inserts or damaged components contribute to sustained productivity and prolong the tool's lifespan.

6. Frequently Asked Questions (FAQs)

FAQ 1: Can Tungsten Carbide Insert Tricone Bit be used for high-speed machining?

FAQ 2: How does the Tungsten Carbide Insert Tricone Bit compare to other cutting tools?

FAQ 3: What are the recommended cutting parameters for optimal productivity?

FAQ 4: How often should Tungsten Carbide Inserts be replaced?

FAQ 5: Are Tungsten Carbide Insert Tricone Bits suitable for both manual and CNC machining?

7. Conclusion

Maximizing productivity in industrial equipment and component manufacturing is crucial for maintaining competitiveness in today's market. By employing Tungsten Carbide Insert Tricone Bit, manufacturers can leverage its exceptional durability, cutting performance, and versatility to enhance productivity. Understanding the application areas, factors influencing productivity, and optimizing tool selection and maintenance contribute to the successful utilization of Tungsten Carbide Insert Tricone Bit. Embrace this innovative cutting tool to unlock your manufacturing potential and stay ahead of the competition.

1. Introduction

2. Understanding Tungsten Carbide Insert Tricone Bit

3. Advantages of Tungsten Carbide Insert Tricone Bit

4. Application Areas for Tungsten Carbide Insert Tricone Bit

5. Factors Influencing Productivity with Tungsten Carbide Insert Tricone Bit

6. Frequently Asked Questions (FAQs)

7. Conclusion

1. Introduction

In the realm of industrial equipment and component manufacturing, efficiency and productivity play a crucial role. This article explores the benefits of utilizing Tungsten Carbide Insert Tricone Bit in maximizing productivity. By delving into the features and applications of this innovative tool, we aim to provide valuable insights for manufacturers seeking to optimize their efficiency.

2. Understanding Tungsten Carbide Insert Tricone Bit

Tungsten Carbide Insert Tricone Bit is a cutting tool widely used in the manufacturing industry. It comprises three rotating cones, each equipped with durable tungsten carbide inserts. These inserts ensure superior durability, high resistance to wear and tear, and excellent cutting performance. With its robust design and precise engineering, the Tungsten Carbide Insert Tricone Bit offers manufacturers a reliable solution for their machining needs.

3. Advantages of Tungsten Carbide Insert Tricone Bit

3.1 Exceptional Durability: The tungsten carbide inserts in the Tricone Bit enhance its durability, making it highly resistant to wear and tear. This longevity ensures extended tool life and minimizes downtime for replacement or maintenance.

3.2 Enhanced Cutting Performance: The precise engineering of Tungsten Carbide Insert Tricone Bit enables it to deliver exceptional cutting performance. Its sharp edges and effective chip evacuation system result in smooth and efficient machining, reducing material wastage and increasing overall productivity.

3.3 Versatility: Tungsten Carbide Insert Tricone Bit is compatible with various materials, including steels, alloys, and composites. This versatility enables manufacturers to utilize the Tricone Bit across a wide range of applications, further enhancing productivity.

4. Application Areas for Tungsten Carbide Insert Tricone Bit

4.1 Metalworking: Tungsten Carbide Insert Tricone Bit finds immense utility in metalworking processes, such as drilling, milling, and turning. Its exceptional cutting performance and durability make it an ideal choice for machining various metals, including stainless steel, aluminum, and cast iron.

4.2 Woodworking: The Tricone Bit is also suitable for woodworking applications. Whether it's creating intricate designs or drilling holes, Tungsten Carbide Insert Tricone Bit offers precision and efficiency, contributing to increased productivity in the woodworking industry.

4.3 Composite Materials: Composite materials, such as fiberglass and carbon fiber, pose unique challenges during machining. Tungsten Carbide Insert Tricone Bit's robust design and cutting capabilities make it an excellent choice for working with composite materials, maximizing productivity while ensuring quality results.

5. Factors Influencing Productivity with Tungsten Carbide Insert Tricone Bit

5.1 Tool Selection: Choosing the right Tungsten Carbide Insert Tricone Bit for specific applications is essential to maximize productivity. Understanding the material properties, cutting requirements, and operating conditions enables manufacturers to select the most suitable tool, ensuring optimal performance.

5.2 Cutting Parameters: Adjusting cutting parameters, including cutting speed, feed rate, and depth of cut, can significantly impact productivity. Optimizing these parameters based on the material being machined and the desired outcome can enhance efficiency and overall productivity.

5.3 Tool Maintenance: Regular maintenance and inspection of Tungsten Carbide Insert Tricone Bit are crucial to ensure peak performance. Cleaning, sharpening, and replacing worn-out inserts or damaged components contribute to sustained productivity and prolong the tool's lifespan.

6. Frequently Asked Questions (FAQs)

FAQ 1: Can Tungsten Carbide Insert Tricone Bit be used for high-speed machining?

FAQ 2: How does the Tungsten Carbide Insert Tricone Bit compare to other cutting tools?

FAQ 3: What are the recommended cutting parameters for optimal productivity?

FAQ 4: How often should Tungsten Carbide Inserts be replaced?

FAQ 5: Are Tungsten Carbide Insert Tricone Bits suitable for both manual and CNC machining?

7. Conclusion

Maximizing productivity in industrial equipment and component manufacturing is crucial for maintaining competitiveness in today's market. By employing Tungsten Carbide Insert Tricone Bit, manufacturers can leverage its exceptional durability, cutting performance, and versatility to enhance productivity. Understanding the application areas, factors influencing productivity, and optimizing tool selection and maintenance contribute to the successful utilization of Tungsten Carbide Insert Tricone Bit. Embrace this innovative cutting tool to unlock your manufacturing potential and stay ahead of the competition.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.