Understanding the Importance of PDC Cutters in Industrial Cutting

Dec 28,2023

Table of Contents:

1. Introduction to PDC Cutters

2. The Evolution of Industrial Cutting Tools

3. The Unique Features of PDC Cutters

4. Applications of PDC Cutters in Industrial Cutting

5. Advantages of Using PDC Cutters

6. Factors to Consider in Choosing PDC Cutters

7. FAQs about PDC Cutters

8. Conclusion

In the realm of industrial cutting, PDC (Polycrystalline Diamond Compact) cutters have emerged as a game-changer. These advanced cutting tools have revolutionized the efficiency and effectiveness of various cutting processes, making them an indispensable component in the industrial equipment arsenal. This article delves into the importance of PDC cutters in industrial cutting and the key factors that make them stand out among other cutting tools.

Over the years, industrial cutting tools have undergone a significant transformation. Traditional cutting tools, such as carbide cutters, faced limitations in terms of their durability, cutting speed, and precision. However, with the introduction of PDC cutters, these limitations have been overcome, setting a new benchmark in industrial cutting.

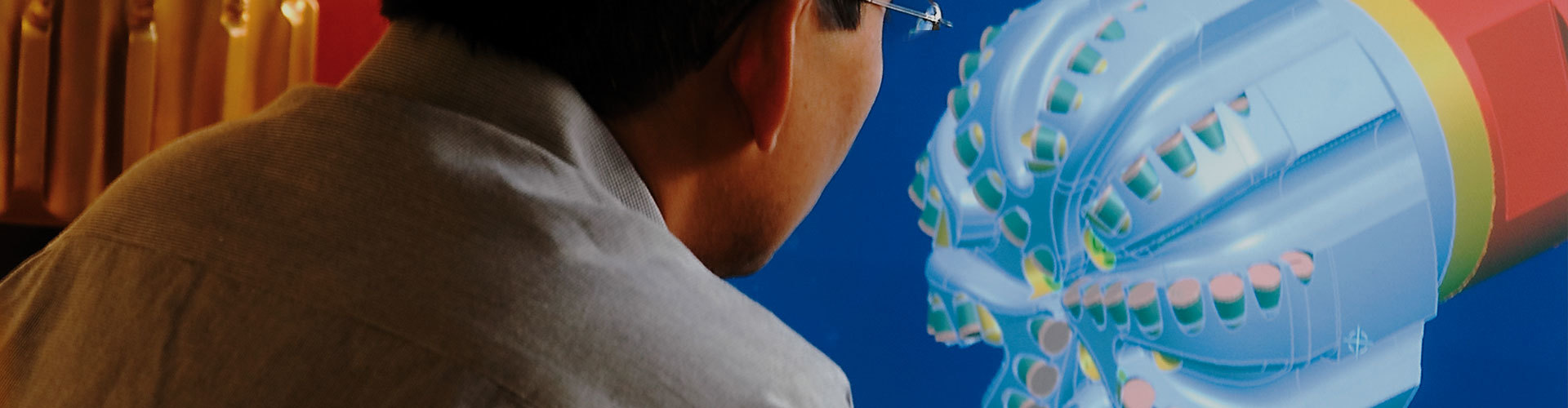

PDC cutters are made from a combination of polycrystalline diamond and tungsten carbide substrate. This unique composition provides exceptional hardness, wear resistance, and thermal stability. The diamond layer on the cutter's surface allows for superior cutting performance, while the carbide substrate provides strength and durability. These features make PDC cutters highly suitable for demanding cutting operations.

PDC cutters find extensive applications in various industries such as oil and gas, mining, construction, and manufacturing. In the oil and gas industry, PDC cutters are widely used in drilling operations, where they exhibit exceptional performance in cutting through hard formations. In mining and construction, PDC cutters are employed in tunneling, road milling, and excavation tasks, ensuring precision and efficiency. Additionally, they are utilized in the manufacturing sector for cutting composite materials, ceramics, and other hard substances.

The utilization of PDC cutters offers several advantages over traditional cutting tools. Firstly, their exceptional hardness and wear resistance allow for prolonged tool life, resulting in reduced downtime and increased productivity. Secondly, the high cutting speeds achieved with PDC cutters enable faster completion of cutting tasks, saving both time and costs. Moreover, the precision and accuracy of PDC cutters ensure clean and superior cutting results, eliminating the need for additional finishing processes. These advantages make PDC cutters a preferred choice in industrial cutting operations.

When selecting PDC cutters for specific cutting applications, certain factors should be taken into account. The type of material to be cut, the required cutting speed, and the operating conditions play a crucial role in determining the optimal PDC cutter design. Additionally, factors such as cutter shape, cutter size, and cutter configuration should be carefully considered to achieve the desired cutting performance and efficiency.

Q1: What does PDC stand for?

A: PDC stands for Polycrystalline Diamond Compact.

Q2: How long do PDC cutters last?

A: The lifespan of PDC cutters varies depending on the cutting conditions and materials being cut. However, they generally offer a significantly longer tool life compared to traditional cutting tools.

Q3: Can PDC cutters be resharpened?

A: No, PDC cutters cannot be resharpened. Once they wear out, they need to be replaced.

Q4: Are PDC cutters expensive?

A: While PDC cutters may have a higher upfront cost compared to traditional cutting tools, their longer tool life and improved cutting performance make them cost-effective in the long run.

Q5: Can PDC cutters be used for both wet and dry cutting?

A: Yes, PDC cutters are suitable for both wet and dry cutting applications, offering versatility in various cutting environments.

In conclusion, PDC cutters have revolutionized the field of industrial cutting, providing exceptional cutting performance, durability, and efficiency. Their unique features and advantages make them an indispensable tool in various industries, ensuring precise and high-speed cutting operations. By understanding the importance of PDC cutters and making informed choices in their selection, industrial cutting processes can be optimized for enhanced productivity and cost-effectiveness. Stay ahead in the cutting game with the power of PDC cutters.

1. Introduction to PDC Cutters

2. The Evolution of Industrial Cutting Tools

3. The Unique Features of PDC Cutters

4. Applications of PDC Cutters in Industrial Cutting

5. Advantages of Using PDC Cutters

6. Factors to Consider in Choosing PDC Cutters

7. FAQs about PDC Cutters

8. Conclusion

1. Introduction to PDC Cutters

In the realm of industrial cutting, PDC (Polycrystalline Diamond Compact) cutters have emerged as a game-changer. These advanced cutting tools have revolutionized the efficiency and effectiveness of various cutting processes, making them an indispensable component in the industrial equipment arsenal. This article delves into the importance of PDC cutters in industrial cutting and the key factors that make them stand out among other cutting tools.

2. The Evolution of Industrial Cutting Tools

Over the years, industrial cutting tools have undergone a significant transformation. Traditional cutting tools, such as carbide cutters, faced limitations in terms of their durability, cutting speed, and precision. However, with the introduction of PDC cutters, these limitations have been overcome, setting a new benchmark in industrial cutting.

3. The Unique Features of PDC Cutters

PDC cutters are made from a combination of polycrystalline diamond and tungsten carbide substrate. This unique composition provides exceptional hardness, wear resistance, and thermal stability. The diamond layer on the cutter's surface allows for superior cutting performance, while the carbide substrate provides strength and durability. These features make PDC cutters highly suitable for demanding cutting operations.

4. Applications of PDC Cutters in Industrial Cutting

PDC cutters find extensive applications in various industries such as oil and gas, mining, construction, and manufacturing. In the oil and gas industry, PDC cutters are widely used in drilling operations, where they exhibit exceptional performance in cutting through hard formations. In mining and construction, PDC cutters are employed in tunneling, road milling, and excavation tasks, ensuring precision and efficiency. Additionally, they are utilized in the manufacturing sector for cutting composite materials, ceramics, and other hard substances.

5. Advantages of Using PDC Cutters

The utilization of PDC cutters offers several advantages over traditional cutting tools. Firstly, their exceptional hardness and wear resistance allow for prolonged tool life, resulting in reduced downtime and increased productivity. Secondly, the high cutting speeds achieved with PDC cutters enable faster completion of cutting tasks, saving both time and costs. Moreover, the precision and accuracy of PDC cutters ensure clean and superior cutting results, eliminating the need for additional finishing processes. These advantages make PDC cutters a preferred choice in industrial cutting operations.

6. Factors to Consider in Choosing PDC Cutters

When selecting PDC cutters for specific cutting applications, certain factors should be taken into account. The type of material to be cut, the required cutting speed, and the operating conditions play a crucial role in determining the optimal PDC cutter design. Additionally, factors such as cutter shape, cutter size, and cutter configuration should be carefully considered to achieve the desired cutting performance and efficiency.

7. FAQs about PDC Cutters

Q1: What does PDC stand for?

A: PDC stands for Polycrystalline Diamond Compact.

Q2: How long do PDC cutters last?

A: The lifespan of PDC cutters varies depending on the cutting conditions and materials being cut. However, they generally offer a significantly longer tool life compared to traditional cutting tools.

Q3: Can PDC cutters be resharpened?

A: No, PDC cutters cannot be resharpened. Once they wear out, they need to be replaced.

Q4: Are PDC cutters expensive?

A: While PDC cutters may have a higher upfront cost compared to traditional cutting tools, their longer tool life and improved cutting performance make them cost-effective in the long run.

Q5: Can PDC cutters be used for both wet and dry cutting?

A: Yes, PDC cutters are suitable for both wet and dry cutting applications, offering versatility in various cutting environments.

8. Conclusion

In conclusion, PDC cutters have revolutionized the field of industrial cutting, providing exceptional cutting performance, durability, and efficiency. Their unique features and advantages make them an indispensable tool in various industries, ensuring precise and high-speed cutting operations. By understanding the importance of PDC cutters and making informed choices in their selection, industrial cutting processes can be optimized for enhanced productivity and cost-effectiveness. Stay ahead in the cutting game with the power of PDC cutters.

Contact Us

ADDRESS:

Junziguan, HejianCity, Hebei province, China.